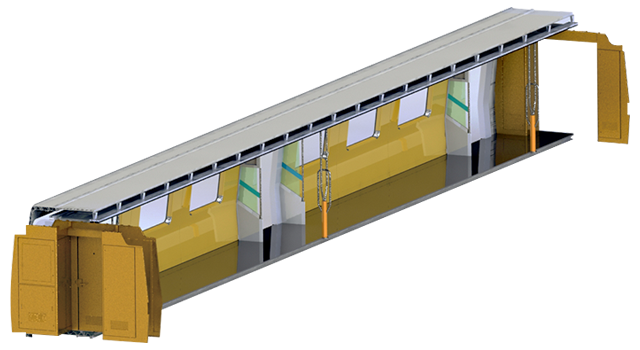

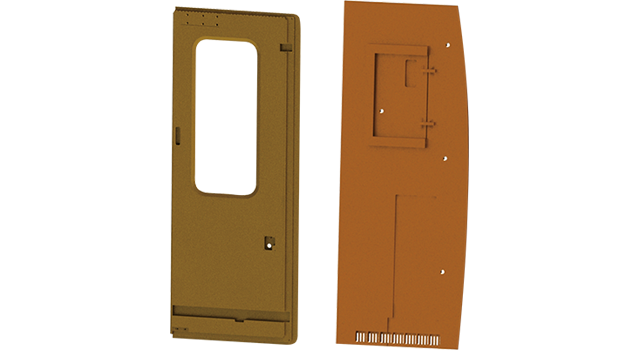

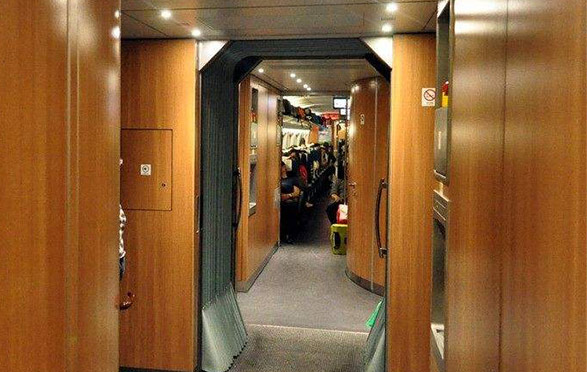

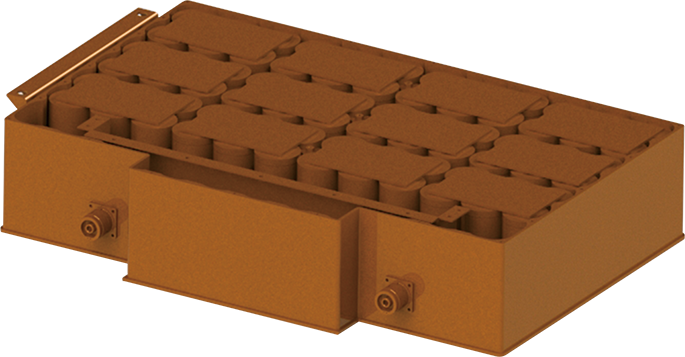

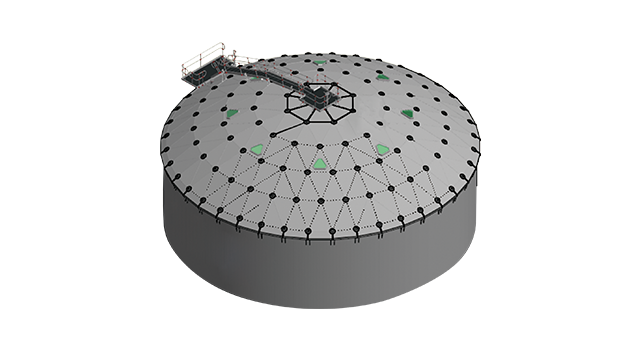

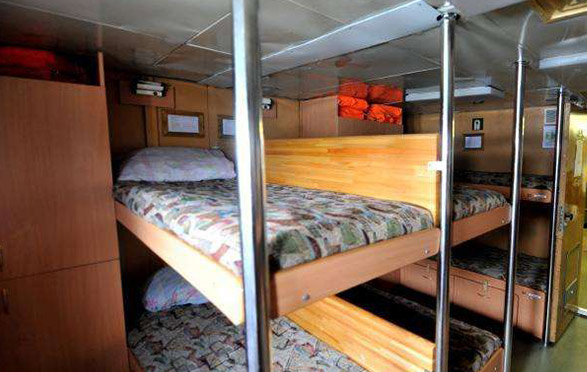

The main business of "Lidao New Material" is to provide high-end colored aluminum, welded honeycomb panel and other new materials for rail transit, new energy vehicles, military industry, petrochemical industry, shipbuilding, construction, industry, food packaging and other industries. High quality raw materials, professional equipment, mature technology and careful operation, create excellent quality, become domestic and foreign high-speed rail subway, new energy vehicles, oil tank body, food packaging and special vehicles and other industries choice.

Standing at a new historical starting point, the company actively responds to the national development strategy of "One Belt and One Road" and "military-civilian integration". And with a keen eye, firmly grasp the market product update and alternation, for new construction, food packaging and material lightweight to provide a high level, all-round overall solution. Actively develop greener, healthier, lighter aluminum honeycomb panels and other products of new materials!